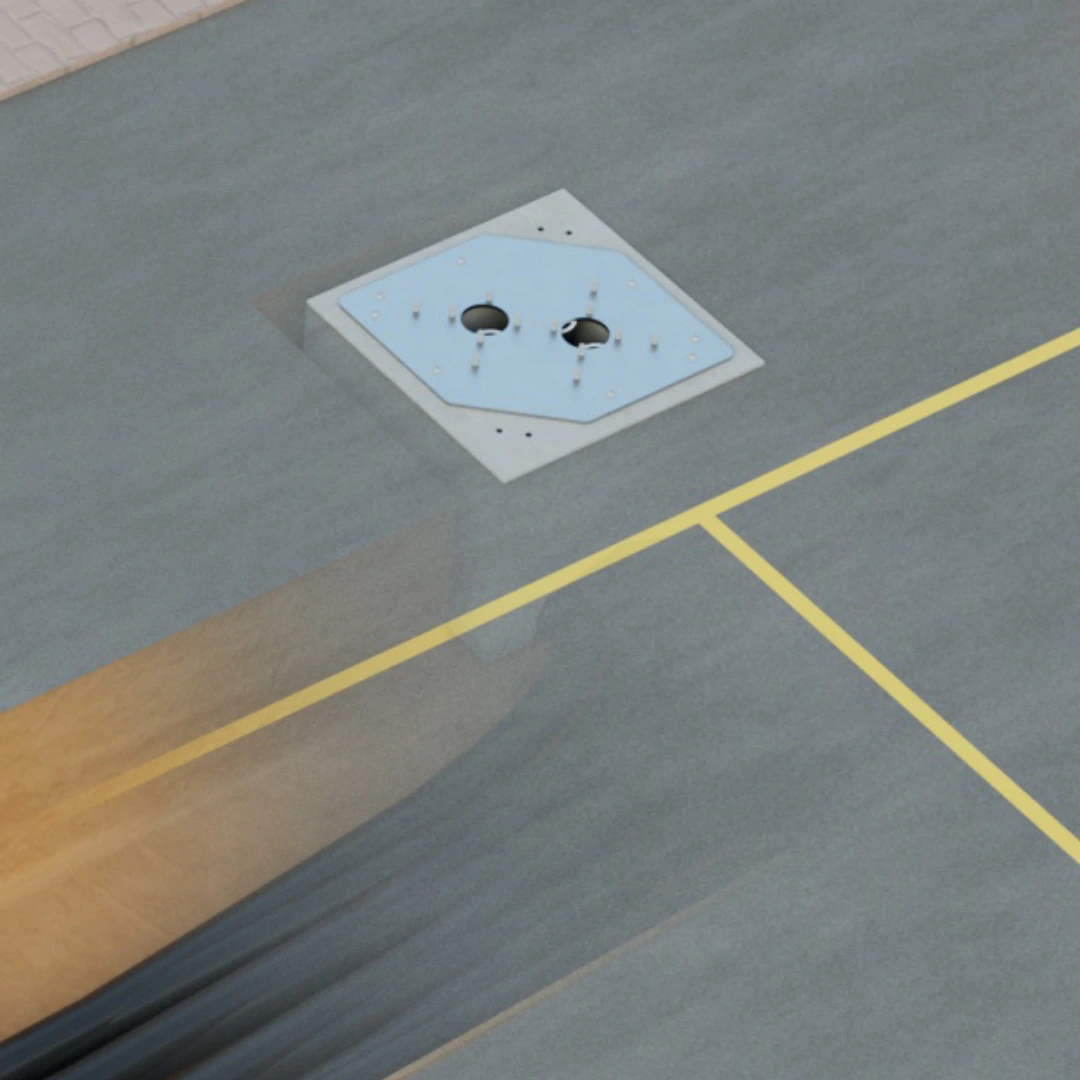

Installation of the the passive adaptor plate

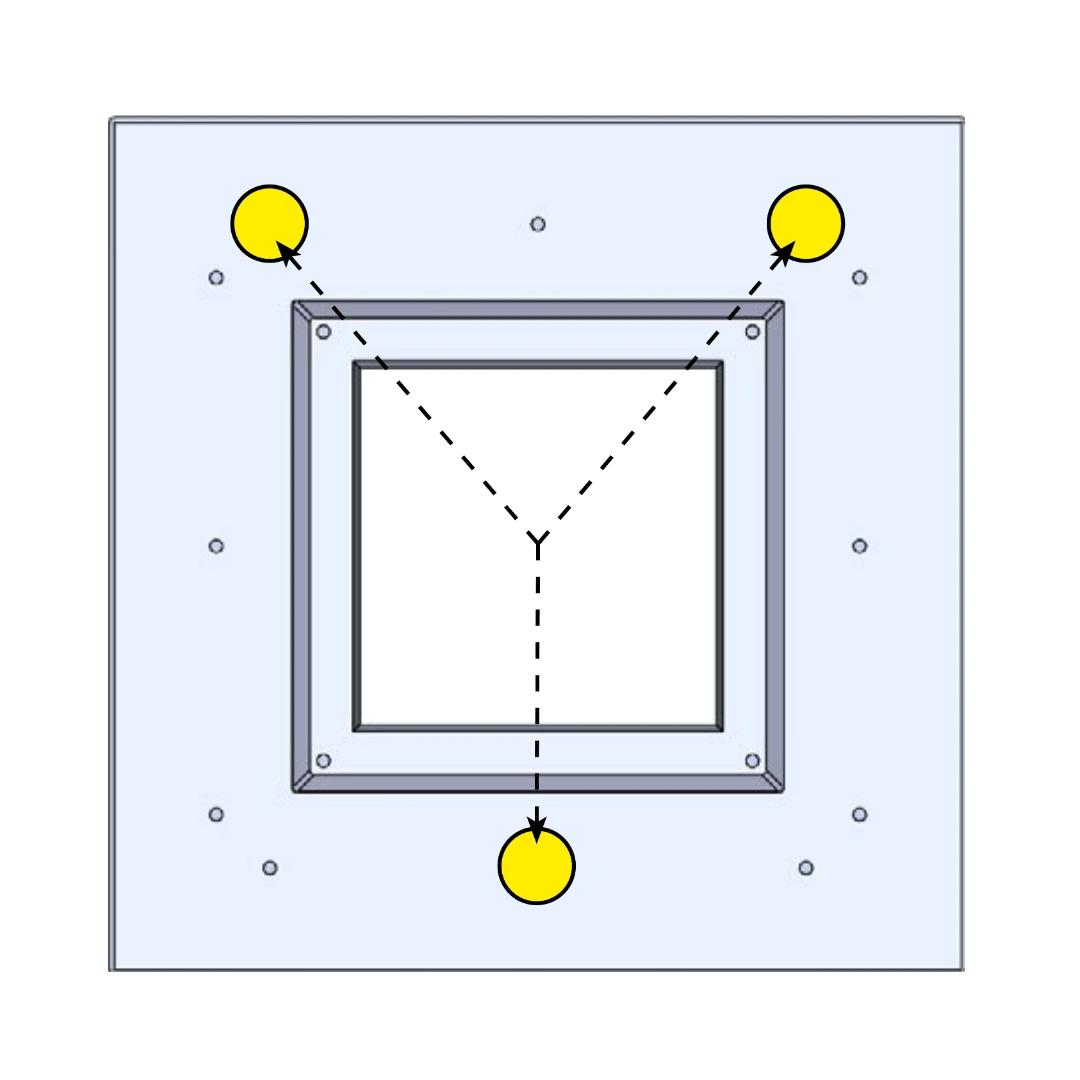

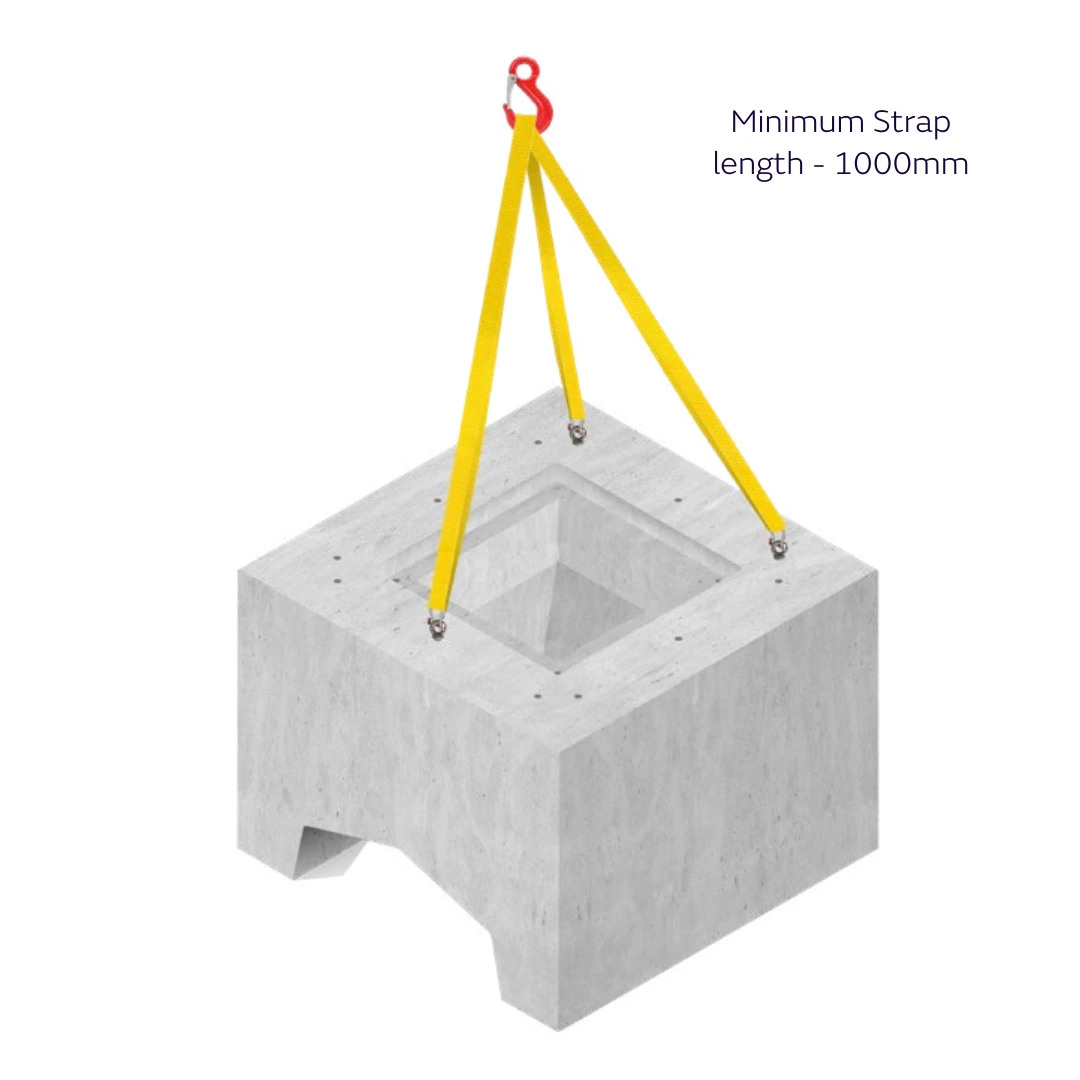

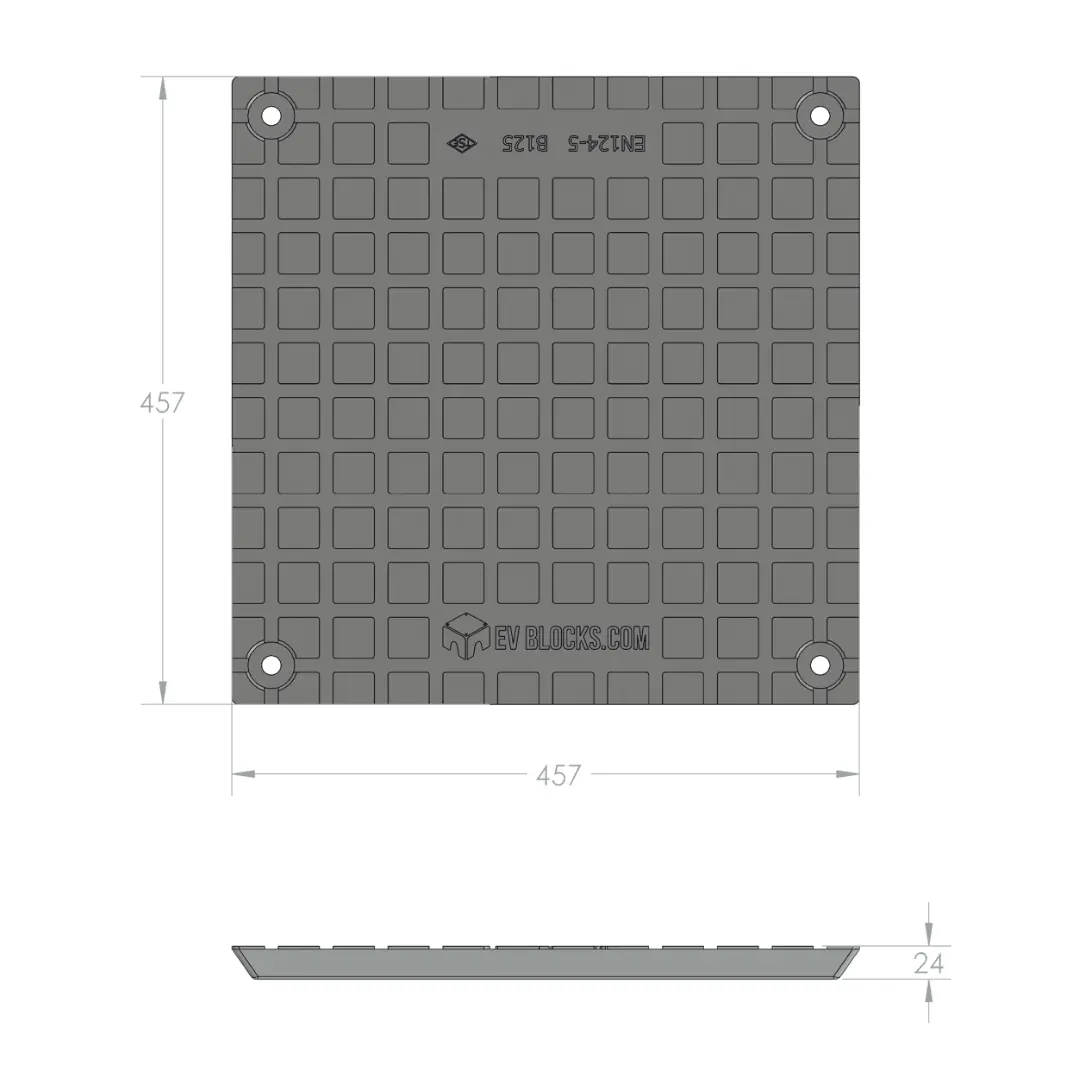

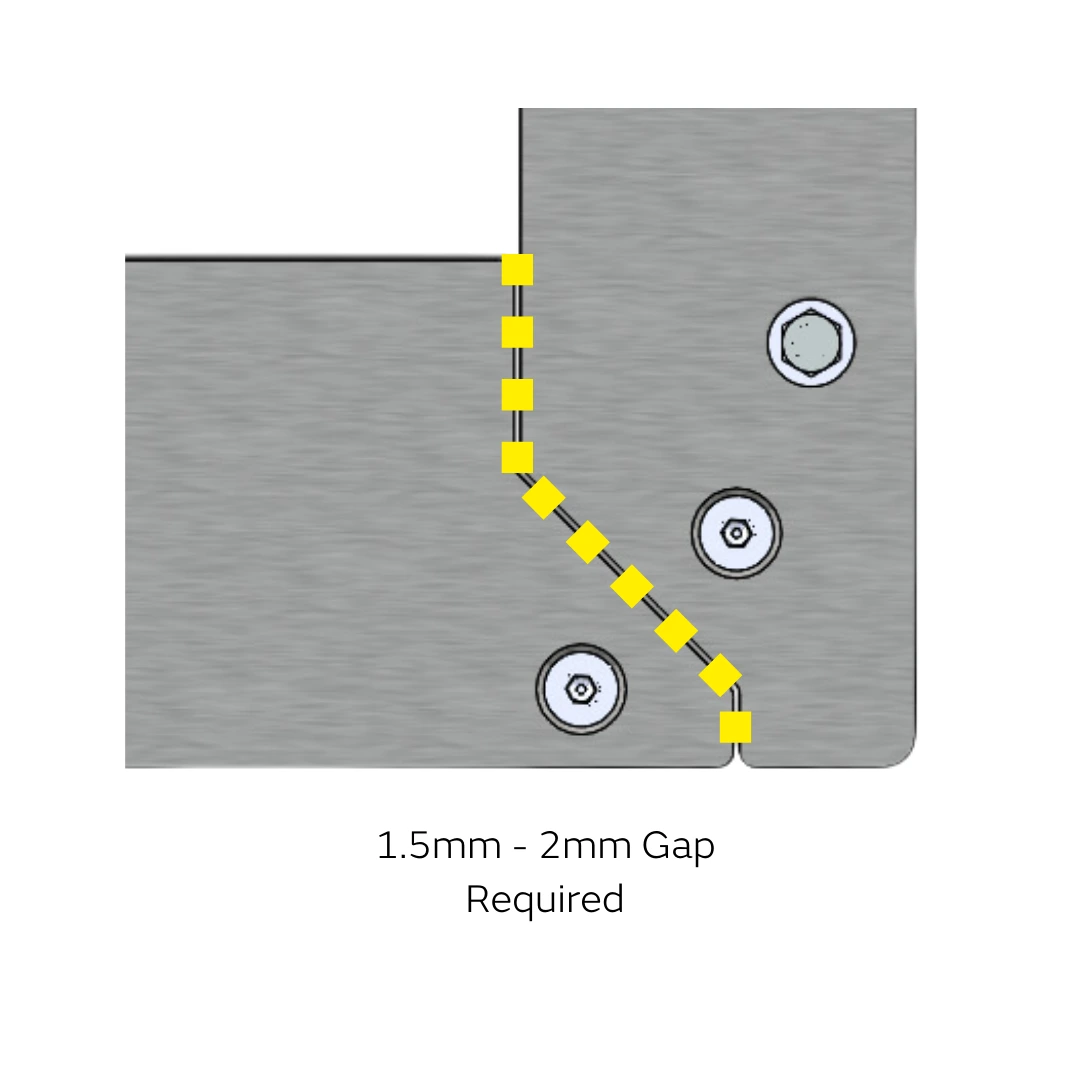

Using the 4 M12x.1.75 Hex-Pin set screw and washers the passive adaptor plate can be secured to the concrete element. The universal design of the B800 allows the EV Blocks the below ground infrastructure to be installed before the EV charger has been specified or selected, future-proofing your project.

Summary

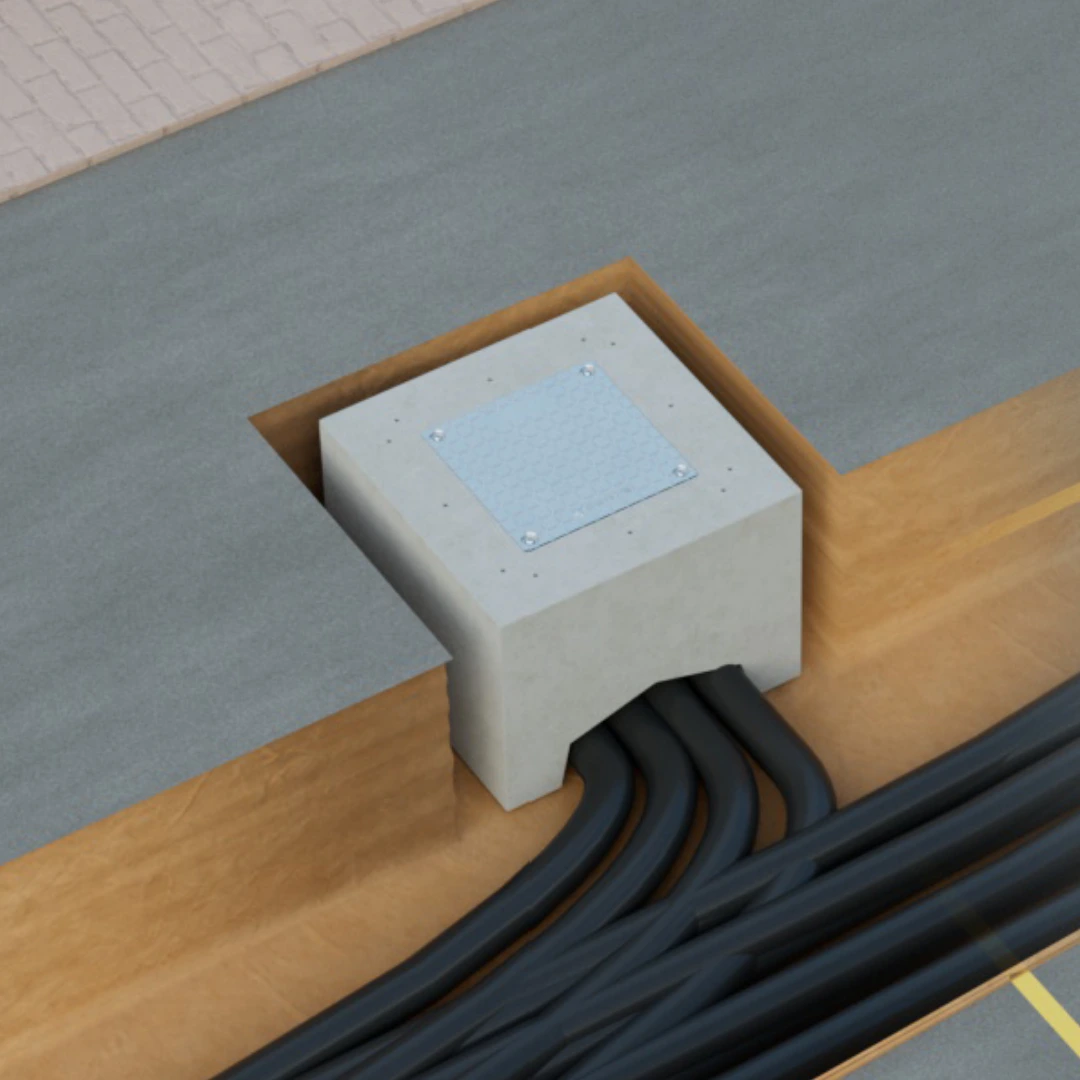

Our passive adaptor plates have a slip resistant surface. This makes the product ideal for installing additional EV charger foundations at relatively low cost as the EV Blocks can be installed in a passive state until cabling and additional infrastructure is required, future proofing sites. Our engineered solution ensures a uniform finish every time. EV Blocks can be installed in any weather conditions, reducing time and lost productivity.