About us

What Are Universal EV Charger Foundations?

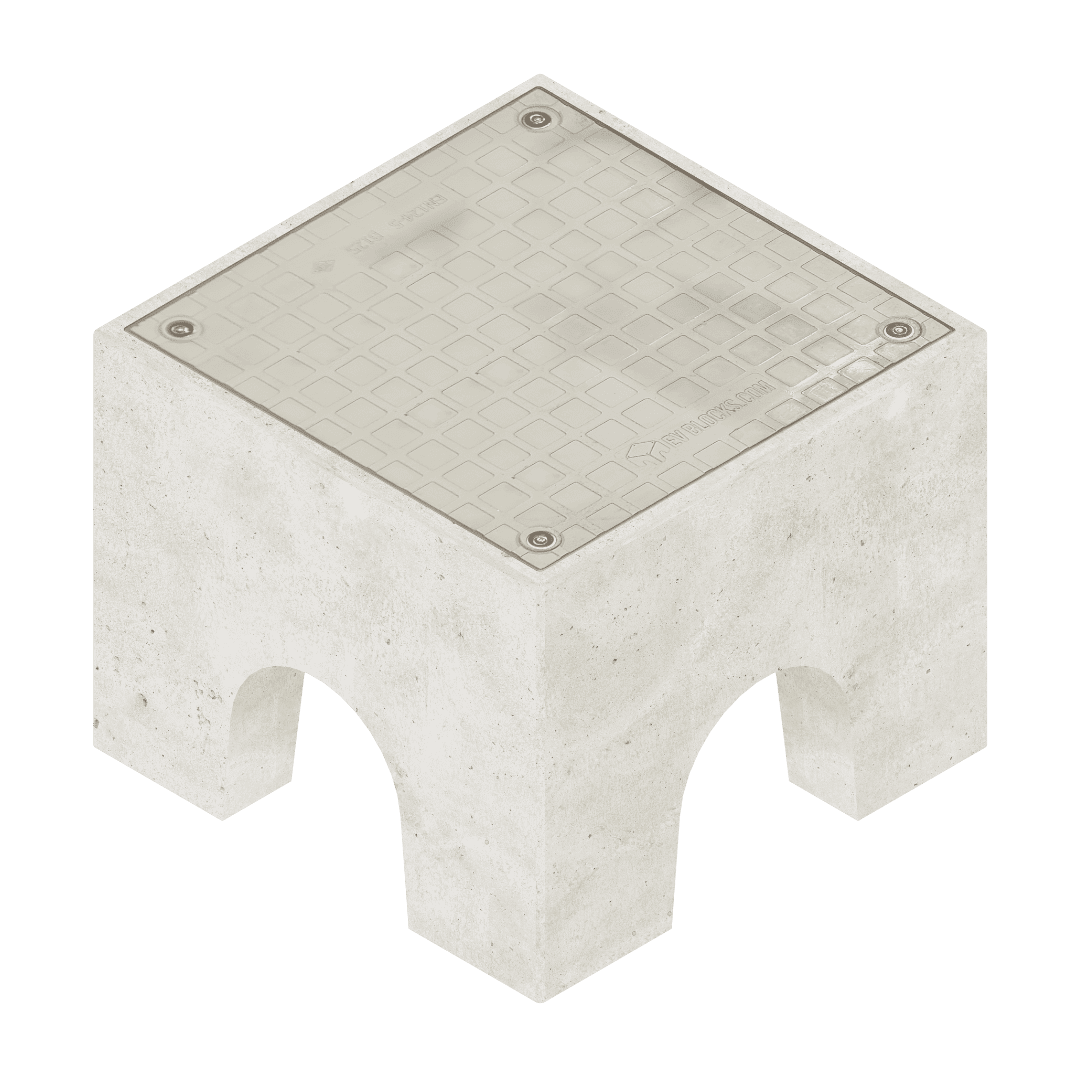

Universal pre-cast concrete EV charger foundations are specially designed and manufactured products that serve as the base for EV charging stations. These foundations are typically made of high-strength concrete and are pre-cast in a controlled factory environment. They can be easily transported and installed at various locations, making them a versatile solution for EV charging infrastructure.

What we do

The EV Block simplifies EV charge point installation. Its precast concrete foundation along with a universal adaptor plate streamlines the process. Eliminating the traditional installation process of “waiting for concrete to cure” that can result in unnecessary costs and disruptions.

Our Mission

EV Blocks pioneers a future-proof standard in EV charging. Our products simplify updates, revolutionising free-standing EV charge point installations. Reducing install time and enabling eco-friendly solutions, committing to a sustainable and efficient mobility future.

Trevor Palmer

Founder & Inventor

Trevor has installed numerous EV charge points in the UK through his 20+ years as an electrical contractor.

He observed businesses’ challenges with excavation, cement pouring for plinths, and fixing arrangements firsthand. To simplify his customers’ lives, he created the EV Block, a precast EV base that accelerates installation.

Keep Me Updated

Stay charged up with the latest news when you sign up to our EV Blocks newsletter.